|

Anytester (Hefei) Co., Ltd

China Atmospheric Plasma Coating System manufacturer |

| Payment Terms: | T/T,L/C,D/P,WU |

| Place of Origin: | Hong Kong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

1. Introduction

HY0260 Atmospheric Plasma Coating System is one kind of surface hardening and surface modification technology. It can make the substrate surface with wear resistance, corrosion resistance, high temperature oxidation, electrical insulation, heat insulation, radiation, wear and sealing performance.

It usually consists of seven parts: Plasma power supply, plasma control cabinet, powder feeder, water and electricity mixed cabinet, plasma coating gun, heat exchanger/cooling system, plasma water cables.

2.Principle:

Plasma coating technology is using a plasma arc driven by a direct current as a heat source, make the ceramic, alloy, metal and other materials are heated to the molten or semi-molten state, and jet/spray to the surface of the preconditioned workpiece to form a strong attached solid surface layer.

3.Technical Specification

(1). Plasma inverter power supply:

Provide DC power for the plasma coating gun, Using IGBT modules, intelligent module control, soft-starting arc, small size, high efficiency, low power consumption, good heat dissipation can work continuously low failure rate is the best plasma power supply.

Item | Parameter |

Input power | 3P AC380V, 50Hz/60Hz |

Output power | 80KW |

No-load maximum voltage | DC125V |

Operating current | 100-800A |

Operating voltage | 30-85V |

Power characteristics | Constant current source |

Current accuracy | <1% |

Load factor | 90% |

Dimension | 650 × 430 × 1600mm |

Weight | 200Kg |

(2). Control cabinet

It can automatically control the spraying process, ignition, soft-start, soft-off; voltage and current adjustable when work; and with water temperature, voltage, water pressure automatic protection function; for water, electricity, gas, powder Regulation and control. It can monitor the entire system, the user can directly understand the system from the control cabinet when the system parameters, such as voltage and current size can be read directly, when the system of electricity and gas have the same requirements, the system will Automatic alarm to remind the user to do the appropriate adjustment. The temperature of the plasma arc is adjusted by adjusting the current and voltage on the panel. Users can also control the main gas through the control panel, the second gas to control the gas flow and gas ratio to change the length of the plasma arc and the flame velocity of the final powder particles to change the speed to ensure the accuracy of repeated experiments, the other control cabinet (Power users can set their own), spraying (power users can set their own), so that customers spray in a long time, need to have a metal powder rendering, it can be (3KW or so) Through a knob to automatically switch parameters, simple, convenient and applicable.

Item | Parameter |

Input voltage | 2P AC220V 50Hz |

Input power | 500W |

Control type | Siemens PLC + relay |

Main gas type and pressure | Nitrogen, argon (0.6-0.8MPa) |

Secondary gas type and pressure | Hydrogen (0.4MPa) |

Nitrogen pressure | 0.6MPa |

Gas use | Argon, argon + hydrogen nitrogen, nitrogen + hydrogen

|

MFC Repeatability | ± 0.2% F.S |

MFC Accuracy | ± 1% F.S |

Output voltage accuracy | ± 0.5V |

Output current accuracy | ± 0.5A |

(3) Powder feeder

It for storing the powder and delivering the powder to the spray gun as required. The main gas of the spray gun is used as a powder feeding gas, and the powder is transported to the outlet of the powder feeder through the rotation of the powder feeding scraper, and the powder is separated from the powder feeding barrel through the gas pressure to enter the spray gun. Adjust the potentiometer on the control panel to adjust the feed speed.

Item | Parameter |

Feeding way | Scraper pressure type |

Powder feeding barrel capacity | 6.0L |

Feeding gas | argon or nitrogen |

Feeding gas pressure | 0.5-0.6MPa |

Feeding speed | 0 ~ 180g / min |

Feeding accuracy | ± 1% |

Feeding gas flow | 400-800L / h |

Dimension | 500 × 460 × 1400mm |

Weight | 50kg |

(4)Water and electricity mixed cabinet

It mixed the water and electricity and sent to the spray gun, providing the high-frequency pulse voltage for gun arc start and detection of water temperature and cooling water spray pressure, lightweight and flexible, easy to drag. Arc performance well, reduces the momentary impact of the nozzle arc.

Item | Parameter |

Input voltage | AC220V, 50Hz / 60Hz |

Rated power | 250W |

Control mode | External control |

Output high-frequency voltage | AC2500 ~ 3000 |

Dimension | 610×480×340mm |

Weight | 30kg |

(5)Plasma coating gun

It for the production of plasma coating operations, the working power can up to 50KW, so it can use high powder delivery power, shorten the spraying time and reduce processing costs. The standard architecture allows for fast hardware replacement

Item | Parameter |

Rated power | 50kW |

Rated current | 100-800A |

Operating voltage | 30-75V |

Dimension | 80*75*190mm |

Weight | 1.5Kg |

(6)Heat exchanger/cooling system

Dual compressor drive to reduce the size of the machine, at the same time the coating guns get better cooling, then extend the life of the nozzle.

Item | Parameter |

Circulating water tank capacity | 250Kg |

Cooling capacity | 35KW |

Operating voltage | 30-75V |

Water temperature fluctuation | 5 ℃ |

Water output pressure | 0-1.3Mpa adjustable |

Output water flow | 6 m3 / h |

Fan power | 85W × 2 |

Input power | 3P AC380V 50HZ/60HZ 13.5KW |

Dimension | 1330×780×1310(mm) |

Weight | 450Kg |

(7)Plasma water & electric cables.

The use of Italian imports PVC pipe, burst pressure high to 6 Mpa, working pressure 2Mpa, the maximum DC current 1000A, rated current high to 650A,. It can long-term continuously working when the working temperature is below 55 ° C

(8)Multi-function coating chamber

It is made of cold plate welding, including box door, observation window dust removal system, lighting system and dust removal system. It with a small, easy to operate, both noise, dust and radiation protection, so particularly suitable for spray coating operation and sample preparation.

Item | Parameter |

Maximum workpiece width | 400mm |

Maximum workpiece length | 600mm |

Dust filter area | >50m2 |

Dusting air volume | >2500m3 / h |

Filtration density | 5mm |

Clearing jet pressure | 0.4-0.6Mpa |

Operating temperature | <100 ℃ |

Compressed air consumption | 0.1-0.3m³ / min |

Two-dimensional gun holding device | |

Minimum setting unit | 1mm (any axis) |

Minimum mobile unit | 1mm (arbitrary axis) |

Fast-moving speed | 100mm / s (arbitrary axis) |

Maximum programming size | 500*300 mm; |

Programming reference point | free to set |

Coating times | can be free set |

Maximum turning diameter | ¢ 200mm |

Workpiece clamp max load | 30Kg |

Power | 3P AC380V 50HZ/60HZ |

Dimension | 1.3*1*1.6m |

(9)Box-type sandblasting machine

Item | Parameter |

Work chamber size | 900mm´800mm´750mm |

Amount of dust removal | 8.5m3 / min |

dust removal motor | 220V, 50HZ, 250W. |

Air source | 5-7 bar (kg / cm2) |

Input power | 220V 50Hz |

Dimension | 900mm´1100mm´1750mm |

Weight | 450Kg |

(10)Air compressor

Item | Parameter |

Volume flow | 3.4m3 / min |

Maximum working pressure | 0.8 MPa |

Motor power | 22 kW (380 V / 3/50 Hz) |

Gas tank volume | 1 m3 |

Frozen dry machine | 4m3/min |

Water output pressure | 0-1.3Mpa adjustable |

Output water flow | 6 m3 / h |

Fan power | 85W × 2 |

Input power | 3P AC380V 50HZ/60HZ 13.5KW |

Dimension | 900mm´1100mm´1750mm |

Weight | 450Kg |

4.Company View

5. Better Quality

a. Our Atmospheric Plasma Coating System adopts top quality material including imported parts. Most of our products are adopting top class supplier inthe world, such as adopt Mitsubishi MCU and converter from Japan, Panasonic servo motor, Jingcai LCD/LED panel, Taikang compressor from French etc.

b. Most of our machine use stainless steel control panel and also some machine body are adopting stainless steel.

c. We have skilled technicians, most of our workers have more than five years working experience.

d. Strict quality control,we have a thorough QC system and we also have top class calibrate machine.

6. Considerate service

We provide different countries' plugs, power voltage 110V and 220V, 380V and other type can be customized, and also we will stick danger tips for our machines.

7. Excellent after-sales service

8. Technical support

a. Installation and training service.

Customer can select installation and training service from us (optional) or accept service from our agent.

b. User manual.

Illustrated user manual of Laboratory Calender can help you operate our machine easily.

c. Operation video

For some of our machines, we can provide you operation video

d. If you meet any problem during operation, you can call us or email us, we will back toyou in 12 hours.

9. Good Packaging

a. Special export wooden cases to protect goods during the shipment also can save your time during custom clearance, because you don't need to provide Inspection Certificate of Fumigation.

b. Machines are covered with preservative film before put machine into the wooden case and fill the case with foam to protect crash between machine and the box.

10. Produce process

11. Commitment

We are province credit enterprise. We will sign a letter of commitment while we sign the contract, which will improve your confidence to us.

12. Transaction process

13. Delivery time

We don't always have all machines in stock, but we can arrange the delivery of our machine in 2 ~ 4 weeks. If you order many machines, please contact us, we will evaluate for you.

14. Payment

We accept payment by Paypal, Western union, T/T in advance, L/C etc. For details, we can negotiate in the contract.

15. Import and export support

We have professional staff to provide you consult on price, tax, insurance, shipment etc. Usually we afford to pack,arrange shipment and prepare export documents etc. If you want to arrange this by yourself, we can provide you support.

If you are not familiar with import, wecan arrange shipment from our factory to your company site and do the custom clearance for you.

Also we can provide you CO, Form A, Form E, CE, CNAS etc. to help you cut down your import tax.

16. Transportation

We have a long-time cooperation shipping company, they have both airline and shipping. So we can arrange delivery for you at low cost and more security. Of course, you can arrange this by yourself if you have a better selection.

17. Target market

Our products are popular in the world, such as South-east Asia, South America and North America, Europe and Central Asia etc.

18. Quick response

We have professional staff to reply your enquiry in 24 hours and provide you solution for your question in 12 hours.

19. FAQ

a. Customer:How about the quality of Atmospheric Plasma Coating System ?

Seller:We have a thorough process of factory inspection. We will inspect all of machines before we send them to customer. Of course, customer can ask for third part inspecting but customer needs to bear this cost.

b. Customer:What about your after-sale service for Atmospheric Plasma Coating System?

Seller: I am glad to tell you that if you select us,then you will work with a passionate team. We are conscientious, diligent andalso they are professional. Their work efficiency may beyond your imagine.

c. Customer: Why your price is a little higher than some others?

Seller:Our price is not the cheapest in the world even in China, but I need to say that our quality is the best at this price.

d. Customer: Is your package stable enough to protect the goods?

Seller:Special export wooden cases and cover preservative film on the machine, then fill the box with foam.

e. Customer: What's your MOQ?

Seller: Our MOQ is 1 set, for more details, you can call us or send us email.

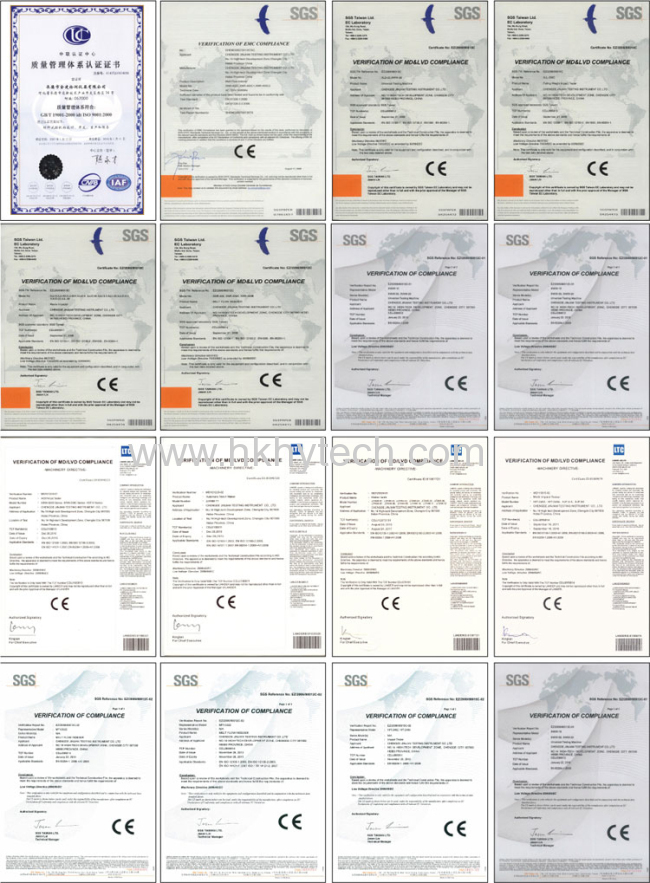

20. Certificate of HY TECH

21. Hot sale!